Product code : BR-1900A

Brand : BRITEX

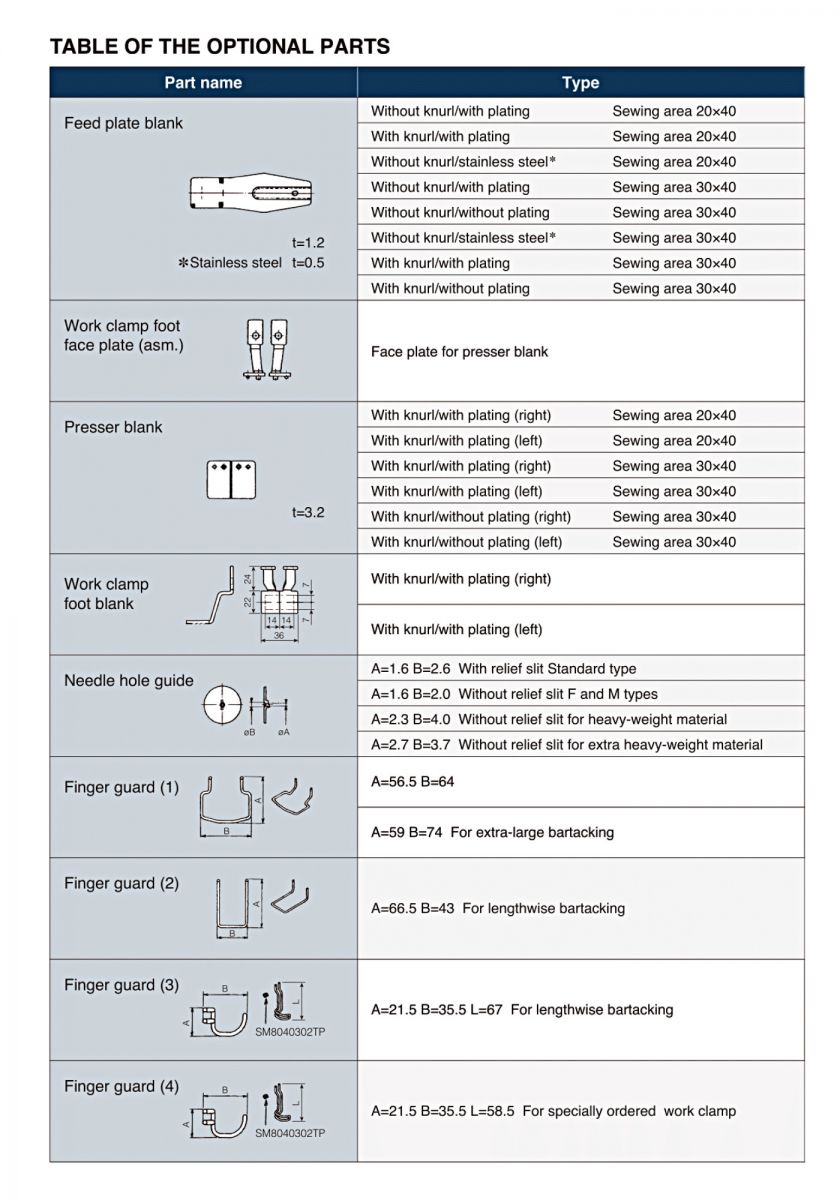

Electronic Computer High Speed Bar Tacking Sewing Machine - Brand: Britex, Model: BR-1900A.

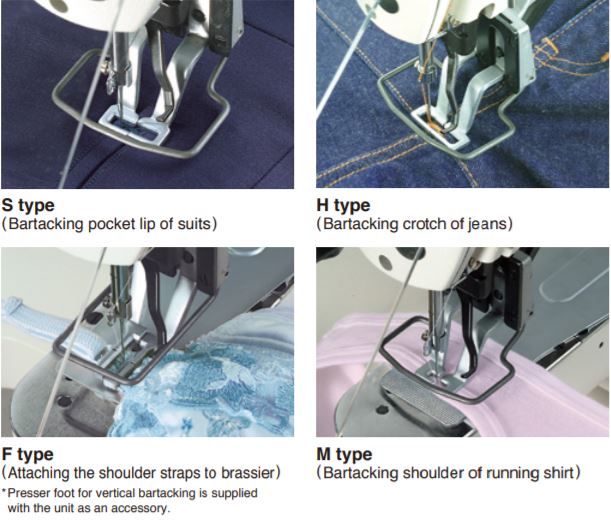

- Different models are prepared according to the type of materials

. A-SS - S type: for standard. Applcated: Bartacking pocket lip of suits

. A-HS - H type: for heavy material. Applicated: Bartacking crotch of jeans.

. A-FS - F type: for foundation. Applicated: Attaching the shoulder straps to brassier. Presser foot for vertical bartacking is supplied with the unit as an accessory

. A-MS - M type: for knits and knitted materials. Applicated: Bartacking shoulder of running shirt.

. A-WS -W type: Large shuttle hook for heavy-weight material and bird's nest prventing / shorter thread remaining functions.

- Control Pannel: By button surface / By Touch screen - optional

- Auto-lifter mechanism utilizing a system

- The sewing starting point can be corrected.

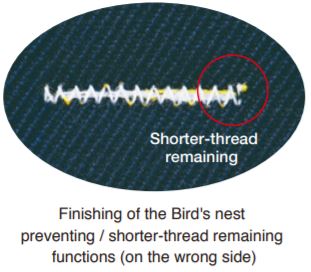

- The sewing machine eliminates so-called “bird’s nests” (thread tangling in on the wrong side of the material at the beginning of sewing)

- Length of thread remaining on the material at the end of sewing has been reduced to 2 mm.

- The machine is provided as standard with the active tension (electronic thread tension control mechanism).

- Oil stains are eliminated.

- Excellent seam quality.

- Higher productivity.

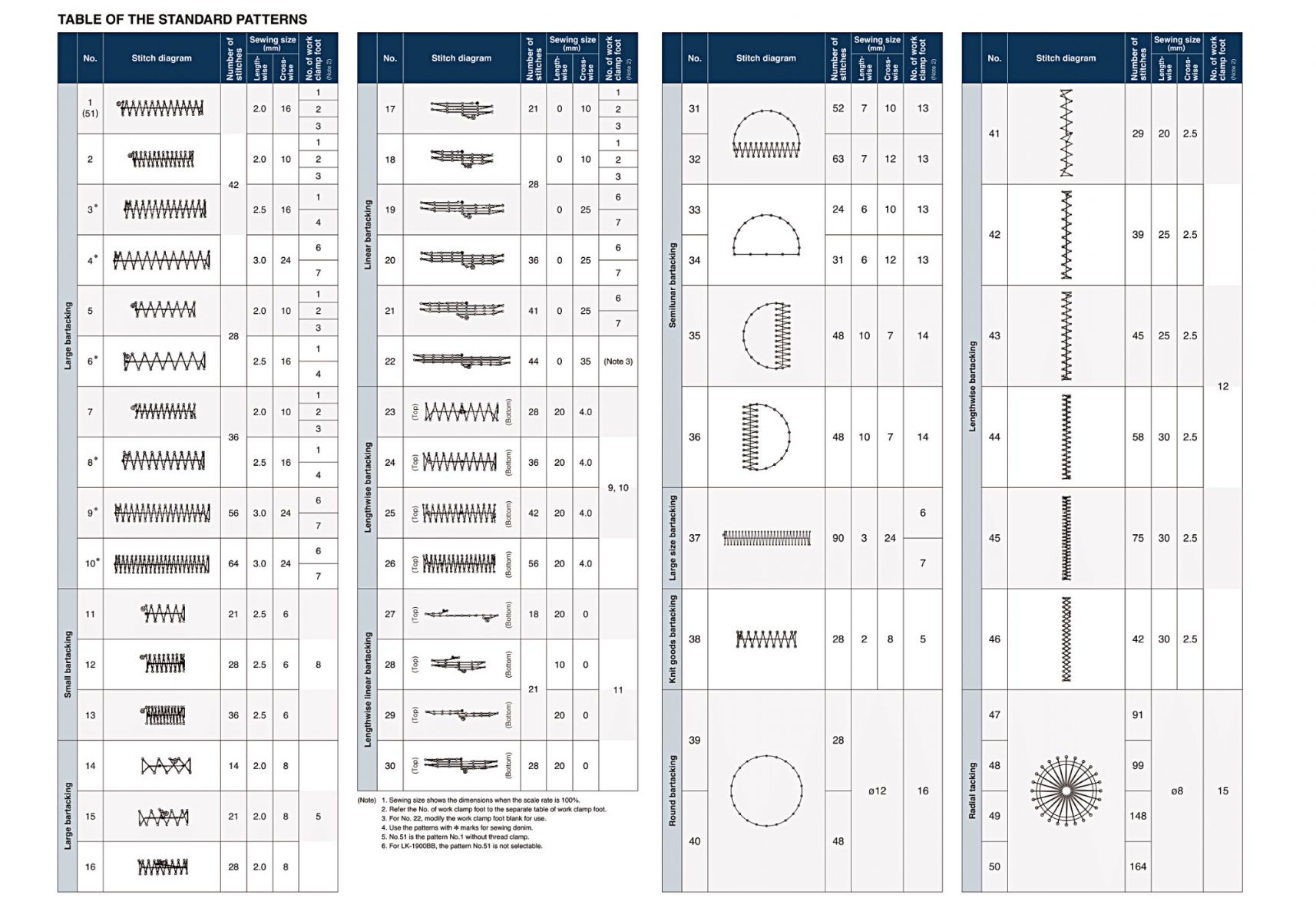

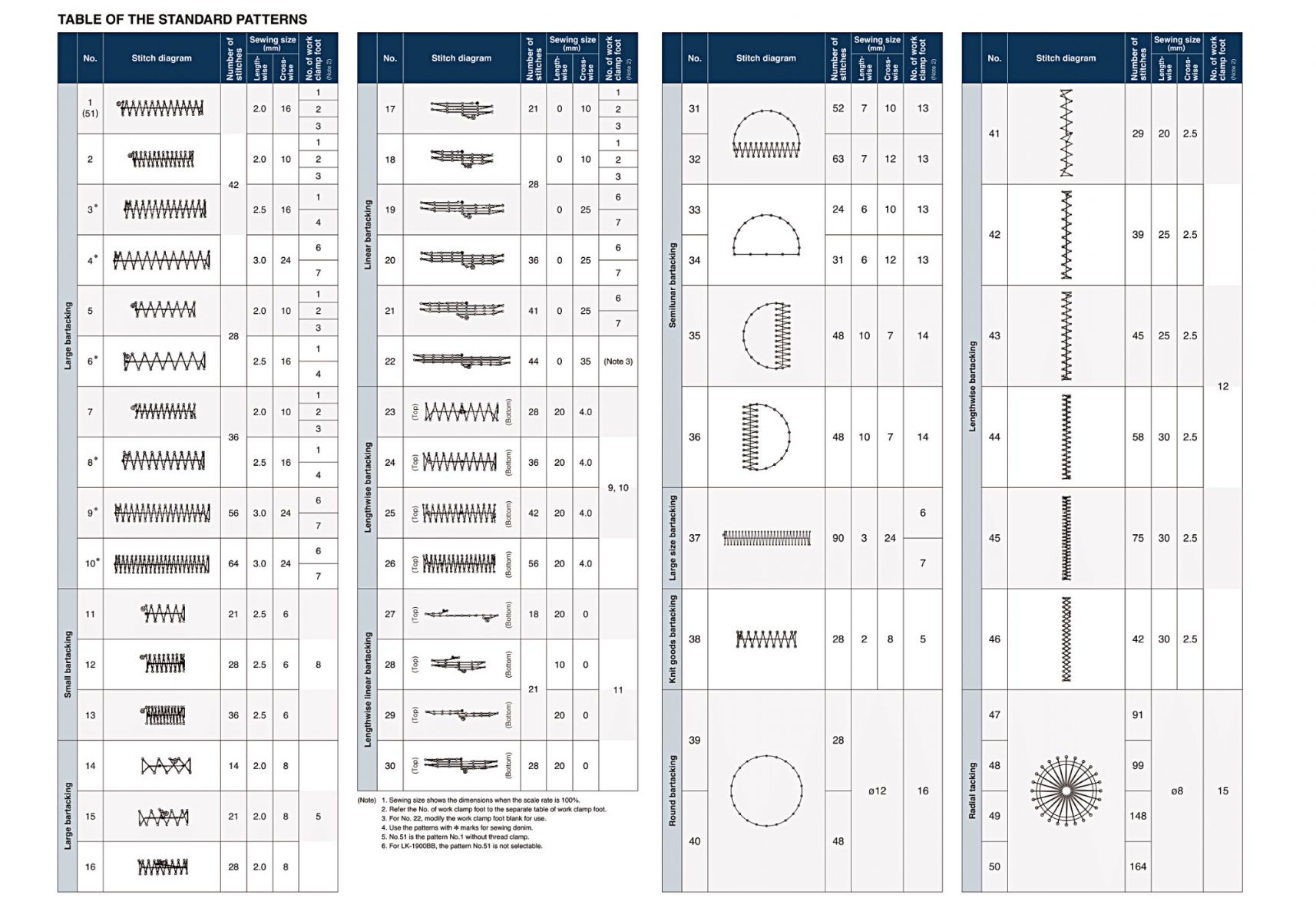

- 50 different sewing patterns.

*** Genuine and Brand new Sewing Machine.

*** Mechanism Guarantee time: 12months, applied for all mechanical mistake by Producer. Mainboard Guarantee: 24 months

Electronic Computer High Speed Bar Tacking Sewing Machine - Brand: Britex, Model: BR-1900A.

*** Different models are prepared according to the type of materials

- A-SS - S type: for standard. Applcated: Bartacking pocket lip of suits

- A-HS - H type: for heavy material. Applicated: Bartacking crotch of jeans. The needle's penetrating force into the material has been increased. This provides an improved responsiveness to heavy-weight materials for the H type machine.

- A-FS - F type: for foundation. Applicated: Attaching the shoulder straps to brassier. Presser foot for vertical bartacking is supplied with the unit as an accessory

- A-MS - M type: for knits and knitted materials. Applicated: Bartacking shoulder of running shirt.

- A-WS -W type: Large shuttle hook for heavy-weight material and bird's nest prventing / shorter thread remaining functions. The W type has adopted a large shuttle hook, which reduces the frequency of bobbin-thread changing to enable highly efficient sewing work.

*** Auto-lifter mechanism utilizing a system: The machine is provided as standard with auto-lifter that uses a stepping-motor system. This helps reduce operator fatigue. It is also possible to change over the stroke of the auto-lifter from a onestep stroke to a double-step stroke, which offers easier positioning of a material on the machine. For the double-step stroke, an intermediate stopping height can be established on the operation panel. The work clamp foot lift can be set to a maximum of 17mm. (Standard 14mm)

- The sewing starting point can be corrected: In cases where the needle entry point for button sewing is to be corrected, the sewing starting point can be corrected without the adjustment of the relevant mechanism.

- The sewing machine eliminates so-called “bird’s nests” (thread tangling in on the wrong side of the material at the beginning of sewing): The thread is retained at the beginning of sewing and any excess thread is trimmed during sewing. As a result, the length of thread sewn in the seam is shortened, thereby achieving high-quality sewing performance while preventing thread from tangling in on the wrong side “of the material.”

- Length of thread remaining on the material at the end of sewing has been reduced to 2 mm: The newly-developed shorter-thread remaining mechanism trims the thread shorter after the regular thread trimming operation. Additionally, thread waste produced by thread trimming is withdrawn by suction. Thanks to this mechanism, the trouble of manual thread nipping is avoided.

- The machine is provided as standard with the active tension (electronic thread tension control mechanism).

- Oil stains are eliminated: Thanks to our advanced dry-head technology, the frame (needle bar and thread take-up) no longer requires lubrication. This prevents the material from being stained with lubricating oil. Just a small quantity of clean oil is supplied from the oil tank to the hook.

- Excellent seam quality: Needle thread grasping mechanism helps produce consistent knot tying at the beginning of sewing.

- Higher productivity: The machine achieves sewing speed of 3,200sti/min. The machine's starting, stopping, thread-trimming and automatic presser lifting speeds have been increased to significantly shorten total cycle time.

- 50 different sewing patterns: The machine is provided as standard with 50 different sewing patterns. The machine permits easy changeover of sewing patterns for effortless execution of an inexhaustible range of sewing specifications.

*** Genuine and Brand new Sewing Machine.

*** Mechanism Guarantee time: 12months, applied for all mechanical mistake by Producer. Mainboard Guarantee time: 24 months

.jpg)