Product code : BR-783NV

Brand : BRITEX

Straight Button holing Machine for double stitch with Gimp - Brand: Britex, Model: BR-783NV

- Neatly tucks in tetron gimps with consistency. Improved locus of the gimp guide.

- A machine is designed for sewing soft-to-the-touch circular bartacks. Able to sew circular bartacks on ladies' wear.

- Ensures stable stitching performance on multi-layered portion of the material. Improved work clamp and its fulcrumsecurely hold multi-layered portions of a heavy-weight material.

- The gimp cutter dramatically promotes lobor-saving. (NB type) The length of remaining gimp after its trimming is only about 2mm.

- A newly introduced mechanism in the needle thread trimmer prevents interference with the positioning of buttonholes. The shape of the face plate is designed to provide sufficient clearance around the needle entry position.

- The work clamp can be lifted as high as 12mm enabling the machine to make high-quality buttonholes in heavy-weight materials.

- Work clamp can be easily lifted. The pressure required to depress the start pedal and lifter pedal has been reduced.

*** Engine:

- No Engine. Connect out source Power by Clutch Motor / Server motor through Belt connection

- D: Direct Drive Motor which can save 40% cost of power. It is convenience for adjust speed

*** Genuine and 100% Brand New Machine.

*** Mechanism Guarantee time: 12months, applied for all mechanical mistake by Producer. Mainboard Guarantee time: 24months.

Straight Button holing Machine for double stitch with Gimp - Brand: Britex, Model: BR-783NV

- The machine neatly tucks in tetron gimps with consistency. Thanks to the improved locus of the gimp guide, the machine is flexibly adaptable to changes in the types of gimps to be used, easily switching operation to accommodate one to three pieces of tetron thread, or one sewing thread and one span thread. In addition, the gimp guide is designed so that it shifts vertically. This means that the relation between the needle and the gimp guide is uniform even if the material thickness varies, thus allowing the machine to tuck in gimps with consistency.

- A machine is designed for sewing soft-to-the-touch circular bartacks. It has been developed to sew circular bartacks on ladies' wear, a process that requires a very delicate finish.

- The machine ensures stable stitching performance on multi-layered portion of the material. The improved work clamp and its fulcrumsecurely hold multi-layered portions of a heavy-weight material, thereby preventing sewing troubles such as uneven material feed, slip-off of gimp and needle breakage. This allows the machine to perform buttonholing with consistency.

- The gimp cutter dramatically promotes lobor-saving. (NB type) The length of remaining gimp after its trimming is only about 2mm. This eliminates the thread cropping procedure in the after-process, thereby increasing productivity. The distance between the gimpcutting scissors and the needle scarcely changes when sewing multilayered portions of the material, thus ensuring consistent gimpcutting at any occasion.

- A newly introduced mechanism in the needle thread trimmer prevents interference with the positioning of buttonholes. The shape of the face plate is designed to provide sufficient clearance around the needle entry position. As a result, ease of operation is further improved.

- The maximum lift of the work clamp is 12mm, enabling the machine to make high-quality buttonholes in heavy-weight Âmaterials.

- Work clamp can be easily lifted. This helps to substantially reduce operator fatigue. The pressure required to depress the start pedal and lifter pedal has been reduced. This helps to dramatically reduce operator fatigue.

- The knife mechanism and stop-motion mechanism produce less noise when they actuate, thus contributing to a more comfortable working environment. Thanks to the simple design of the stop-motion mechanism and unique knife mechanism, the machine operates with low noise. The machine starts, decelerates and stops smoothly.

*** Engine:

- No Engine. Connect out source Power by Clutch Motor / Server motor through Belt connection

- D: Direct Drive Motor which can save 40% cost of power. It is convenience for adjust speed.

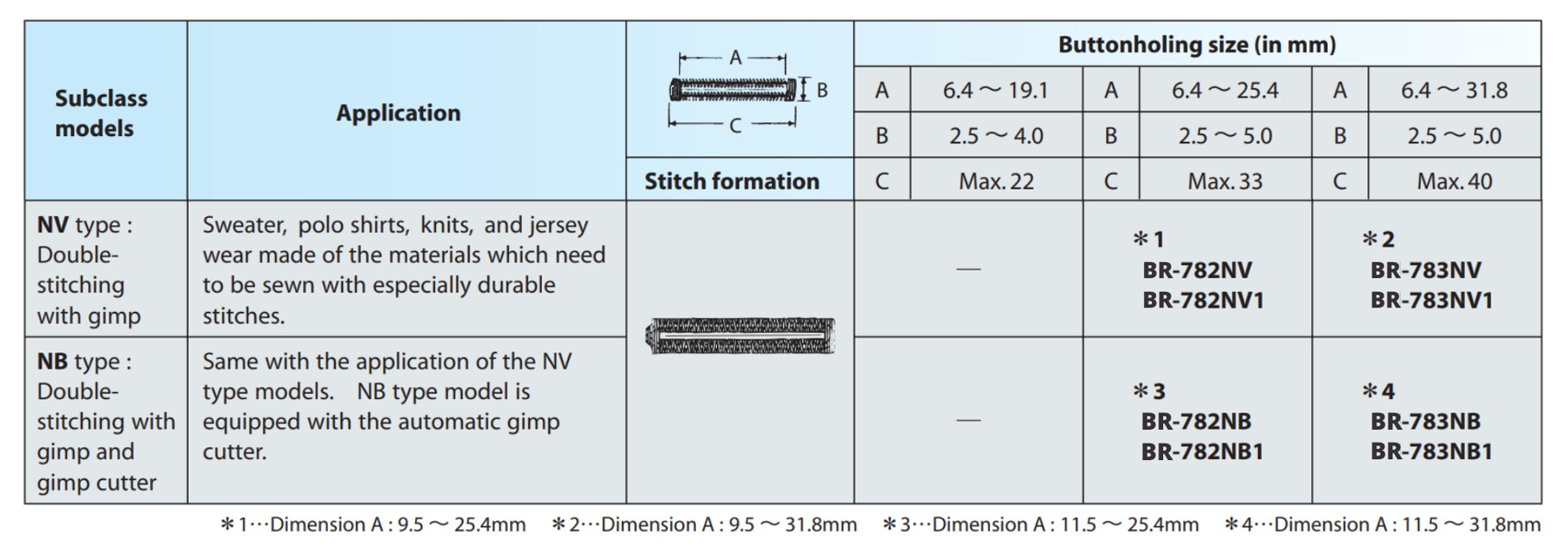

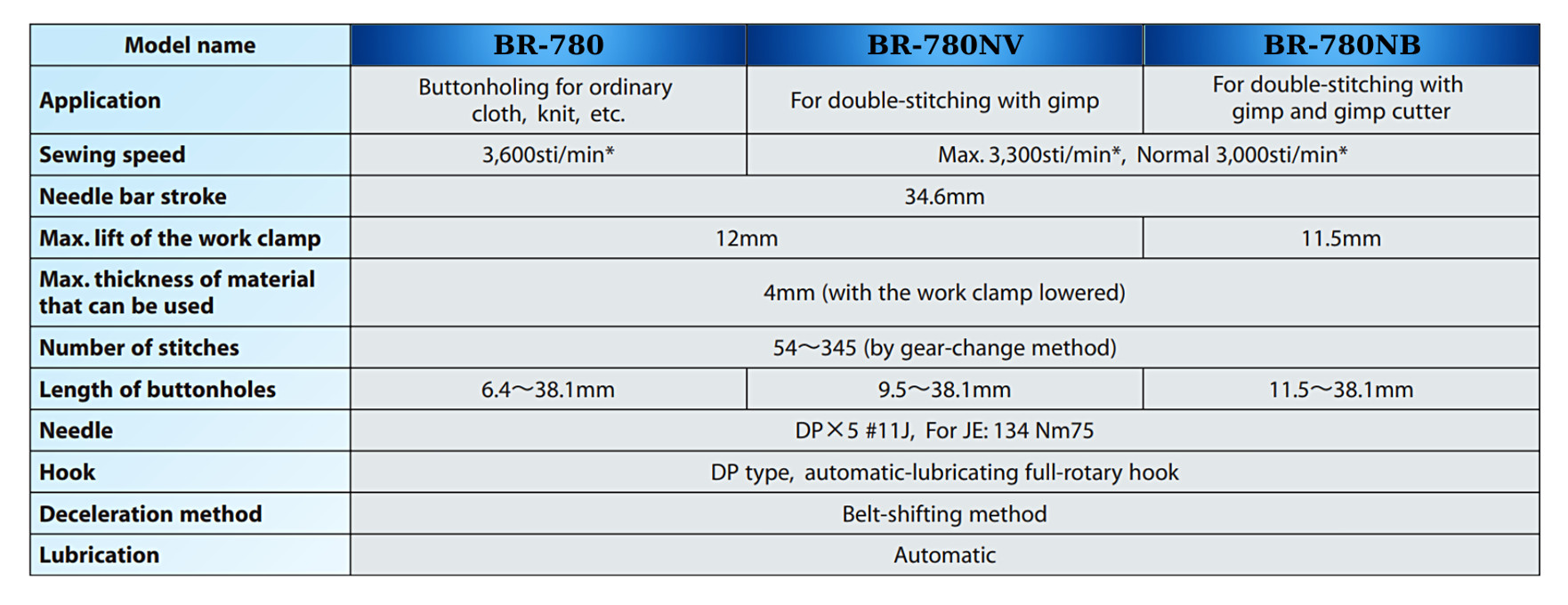

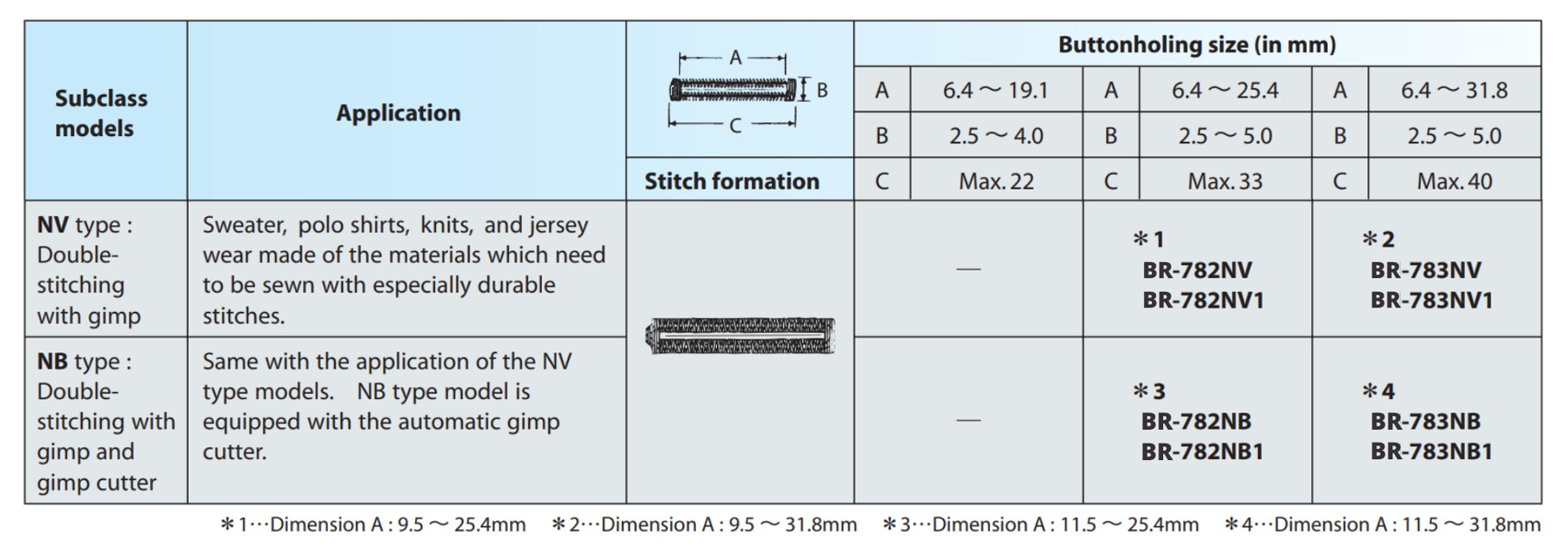

*** Application Type:

+ Symbol by letter

- NV type - Doublestitching with gimp: Sweater, polo shirts, knits, and jersey wear made of the materials which need to be sewn with especially durable stitches.

- NB type - Doublestitching with gimp and gimp cutter: Same with the application of the NV type models. NB type model is equipped with the automatic gimp cutter.

+ Symbol by Number:

*** Detail Image of Product:

*** Genuine and 100% Brand New Machine.

*** Mechanism Guarantee time: 12months, applied for all mechanical mistake by Producer. Mainboard Guarantee time: 24months